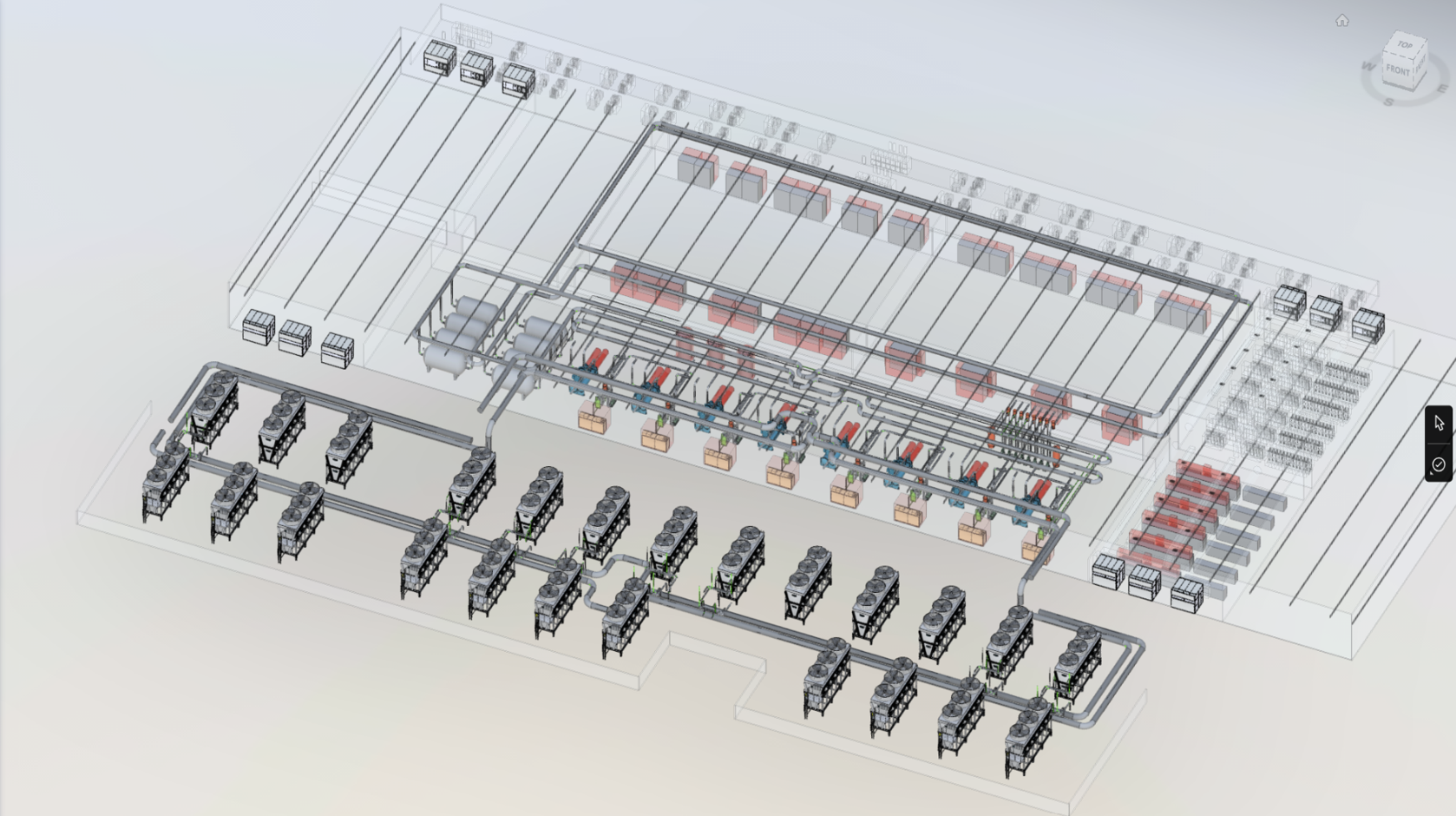

closed-loop cooling Sytem

Sustainable, water-responsible design that protects Lake Ontario

The Lake Mariner Campus features a fully sealed, closed-loop cooling system that continuously recirculates the same fluid, eliminating the need to draw from or discharge into Lake Ontario. The system employs air-cooled dry coolers instead of evaporative towers and uses only food-grade, non-toxic glycol for freeze protection.

Fluid renewal occurs only every 7–15 years and is performed in a fully contained process that meets state and federal environmental standards. This design ensures zero water withdrawal, zero discharge, and continuous operation — fully aligned with TeraWulf’s commitment to sustainable digital infrastructure.

how it works

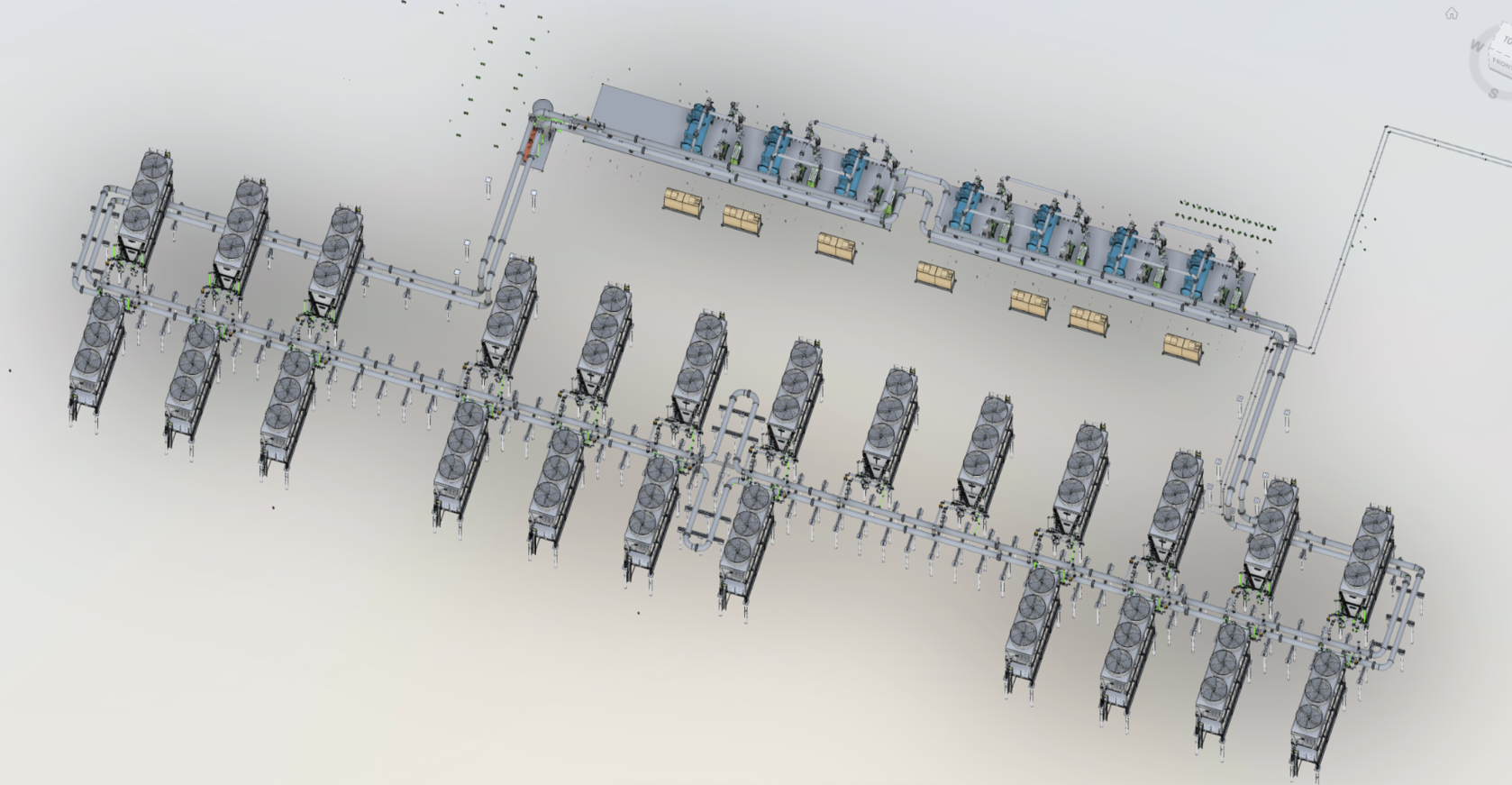

Inside the data halls, chilled water circulates through rear-door heat exchangers attached to server racks. As the servers operate, heat transfers to the fluid, which travels through sealed piping to the mechanical plant.

There, plate-and-frame heat exchangers isolate the chilled-water loop from a separate condenser loop, which carries the heat to air-cooled dry coolers outside the building. Large fans reject heat to the air without evaporating or consuming water.

The cooled fluid then returns to the data hall, repeating the cycle in a continuous, self-contained loop.

operations, maintenance, & longevity

-

Zero water withdrawal or discharge to Lake Ontario or any local source

No evaporative cooling towers or blowdown

Non-toxic, food-grade propylene glycol formulation

Minimal maintenance, with long fluid life (7–15 years)

High system reliability and redundancy (N+1)

Consistent with TeraWulf’s sustainable design principles

-

Although sealed, the system is designed for a long service life with occasional fluid renewal. Every 7–15 years, the glycol-water mixture is drained into sealed tanks, collected by licensed contractors, and either recycled or treated at a certified facility.

The loop is then refilled with new deionized water and food-grade glycol, re-pressurized, and resealed for continued operation. The process is fully contained and compliant with NYSDEC and EPA environmental regulations.

-

Maintenance does not require a data center shutdown. The cooling system is designed with N+1 redundancy and valved isolation segments, allowing one loop to be serviced while others remain active.

Work is scheduled during cooler weather or low IT load periods, with continuous monitoring to ensure stable operation throughout.

inside the loop

This fully contained design delivers sustainable temperature control — no evaporation, no waste, just continuous performance.